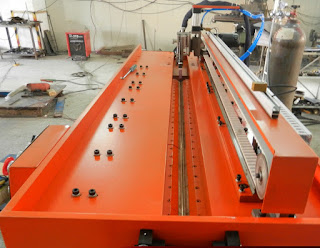

Designed and built with a boom

length as per the clients orders, Boom welding manipulators facilitates a

raised roof section to accommodate the height of the large column. The raised

roof was though later invented allowing for a crane to hoist the manipulator

and then delivered to the customer. Welding manipulators like Column & Boom

Welding machine is often used when referring to welding positioning equipment. A

welding manipulator is a column with a boom arm which is used for holding the sub

arc welding heads and flux over a rotating tank or vessel.

The boom and column weld

manipulators are used in conjunction with other pieces of positional equipment.

The boom offers variation of speed in the reach and the column provides

constant speed lift of the cantilevered boom arm to the height needed for

welding the part. Some of the column and booms are powered reach and manual

hand crank reach.

These boom weld manipulators are

mostly smaller in size units where just a torch or welding feeder is mounted on

the end of the boom gantry arm. Most units of these machines are power

elevation but some are counter balanced hand crank design. The positioners and

rotators are the main parts of these manipulators.

Column

& boom welding manipulators

are available in all sizes in pyramidweld.com.

You can find small as a 2'X2' up to 30'X30' manipulators and even larger in the

website. They offer high quality manipulators made using the standard checked materials

to manufacture the machine. They can offer you manipulator with a complete

submerged arc welding package or automated tig welding system. They manufacture

these machines using highly qualified technicians, choosing the proper

equipment for your industrial fabrication needs.