Machines have been helping the

human race in different sections of life for years. Machines are surely made by

human but the efficiency they revert back to human is incredible. One such

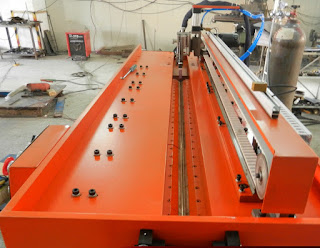

valuable machine is the longitudinalseam welding machine. Now, you can even avail automatic longitudinal

seam welding machine. It is composed of a body, work piece positioning

mechanism, welding torch longitudinal running mechanism, work piece pressing

mechanism, torch lifting and adjusting mechanism.

Features:

|

|

longitudinal seam welding machine

|

· The welding

torch pneumatic moves up and down and therefore, the work piece is fixed and seam

is flat.

· Welding

torch can be up, down, left and right, forward and backward and various other

angles adjusted in order to meet the welding requirements.

· It includes

work pieces positioning and centering by pneumatic, pneumatic keys and welding

position cannot offset.

· The welding

form can be preset, stored and transferred through the man-machine interface.

It can easily change the parameter and state transition.

· The whole

machine is controlled by PLC and the AC variable frequency speed regulation

ensures the equipment reliability. On the other hand copper backing strap

ensures reverse side forming.

The Positioning Of The Equipments:

· The body of

the is constructed using welded square tube and sheet steel, work table below,

work piece positioning and clamping mechanism are on it. Above is gantry

beam, mounted with welding longitudinal running mechanism.

· The

workpiece positioning and centering mechanism happens using the pneumatic block

for centering.

· The work

piece clamping mechanism takes place with the use of mandrel and pneumatic

pressure key plate to clamp and press work piece. The pressure of the workpiece

is uniform and thus, the seam and the clamping area illumination does not

damage the operator’s eyes.

Longitudinal Seam Welding Machine

helps in creating a pressure work for maintaining the seam in proper alignment

as the work passes the welding. Automatic Longitudinal Seam Welding Machine is

used mostly by the industries for the automatic and continuous seam welding of

tubular sections.

Wow this is great! But if you are looking for Auweld brands, you can find them here Industrial Products Clark

ReplyDeleteAs the switching is ON and the primary filter capacitors charges via resistors, the power is further zeroed by turning the switching ON the relay. my site

ReplyDelete